-

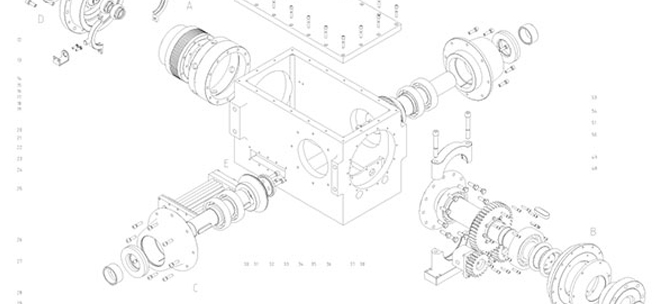

FABRICACIÓN DE MAQUINARIA INDUSTRIAL

-

INGENIERÍA DESAROLLO DE PROYECTOS

-

MANTENIMIENTO DE MAQUINARIA

-

FABRICACIÓN POR MECANIZADO

Volund Group has a proven experience of over 30 years in the design and manufacture of machinery for. A través de los años ha diversificado su oferta a diversos sectores de la industria. Inició su trayectoria con la construcción de motores navales Diesel de bajas revoluciones. Currently services have expanded, counting with satisfied customers around the World.

Sectores de actuación:

- Power Generation and Renewable

- Steel industry

- Paper industry and rubber

- Food industry

- Naval industry

- Mining and mineral processing, aggregates and cement

- Recycling plants and treatment of MSW

- Treatment plants and sewage treatment WWTP

- Desalination and water purification.

- Processing plants salt.

Volund Group offers personalized service from the moment. Analizamos su maquinaria para identificar los puntos de mejora aplicando la solución apropiada en cada caso.

It will have excellent advice by our expert team, both when traveling to their facilities and through telephone consultation. We offer quality technical advice; the answer that best suits the needs of your industry.

We have a long history of providing solutions to industries year after year continue to put their trust in us.

Volund Group provides its guests more than 30 years of accumulated knowledge in the design, construcción y mantenimiento de maquinaria industrial ofreciendo a sus clientes la capacidad para actualizar su maquinaria al momento en que la adquirió.

Es posible obtener un rendimiento superior mediante la automatización, multiplying its performance and expand its capabilities.

Key Benefits

- Increased accuracy and performance.

- Prevention of potential breakage in the future.

- Correct operation of all functions of the machine increasing productivity.

- Decreased ability costly accidents.

- Availability Discontinued component manufacturing.

- Expert team to detect the components causing the anomaly.

Maintenance and repair common:

- Correction removing metal deformation and corrosion.

- Cutting and Metal.

- Repair or replacement of electrical components.

- Grinding dimensional parts.

- Axis Machining, pinions and ring gears.

- Arc welding electrical components, TIG or MIG.

- Cleaning, Repair or replacement of lubricating systems.

- Repair of hydraulic or pneumatic.